Saved 70% on Quality Costs with Loading/Unloading Automation 🙏 (ft. Hyundai Robotics Industrial Robots)

💡 In Just 5 Minutes, You’ll Learn:

Why the customer requested loading/unloading automation

Key features & differentiators of this project

Step-by-step process of the loading/unloading automation

Why Hyundai Robotics’ industrial robot HH050 was selected

How to achieve 100% success in loading/unloading automation

Hello! This is Marosol, Korea’s No.1 Robotic Automation Platform. 🙌

Today, we’re excited to introduce an automation project we successfully completed in Q3 2024.

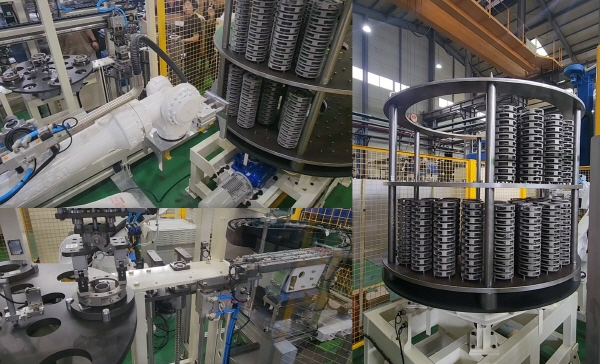

This project was applied to the stacking process of the Carrier Mid-Planet, a critical part of automotive transmissions.

We designed the system so that both loading/unloading and heat treatment processes are automated using an industrial robot and custom jigs.

We also had a brief interview with Marosol Engineer Jisub Han, who led this automation project to success. 🎤

Applied at Samrak Heat Treatment, a specialized company for automotive parts heat processing

Q1. Why did the customer request automation in the first place?

Engineer Han:

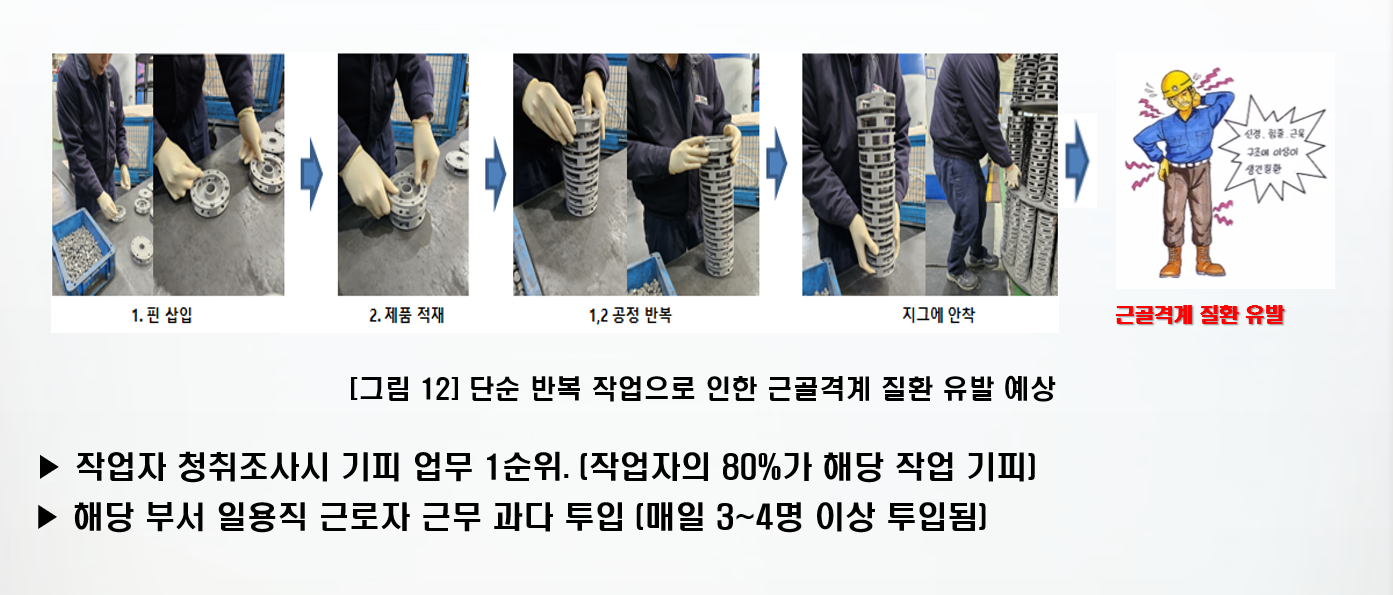

The project was initiated to solve problems caused by manual operations.

Previously, operators manually stacked Carrier Mid-Planet parts and placed them onto the heat-treatment jig. As a result:

Human errors occurred frequently

The defect rate remained high

Operators suffered from fatigue due to physically demanding, repetitive work, leading to decreased efficiency

The customer requested automation to resolve these issues.

Before automation – operators manually moving and stacking products

Q2. What are the key features of this automation project?

Engineer Han:

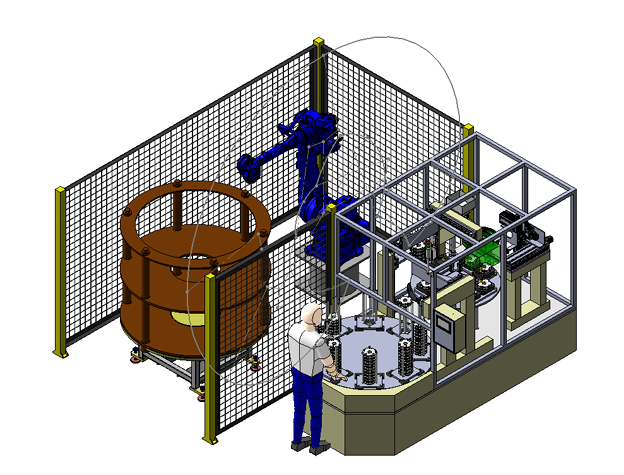

The biggest feature is that we developed a customized layout tailored to the customer’s requirements.

This wasn’t just simple process automation. Instead, we fully automated both pin insertion and stacking, enabling stable production of 720 units per hour.

With manual work, it was nearly impossible to guarantee consistent quality. Now, with automated loading/unloading, the customer can maintain uniform product quality, which is a major advantage.

Q3. How does this project stand out compared to similar ones?

Engineer Han:

Another key differentiator is that we designed a system that is flexible for future model changes.

In simple terms, if the customer wants to adapt the line to a new product later, they can modify the automation without additional cost.

By applying a simple model-change mechanism, the solution provides long-term scalability and flexibility.

Source: Marosol Technical Proposal

Q4. Could you walk us through the automation process step by step?

Engineer Han:

The workflow is divided into four main stages:

1. Product Loading

The operator manually places 20 Mid-Planets at a time into a loading jig, which was also designed to fit the customer’s work environment.

The jigs are set on an 8-division index table, allowing up to 160 units to be prepared.

(Jig: a fixture that holds workpieces in place during processing)

(Index Table: a rotating table that positions workpieces for different operations)

2. Pin Insertion

Pins for stacking are automatically supplied and aligned via a parts feeder.

A single-axis robot equipped with an air chuck inserts the pins precisely into each Mid-Planet.

(Parts Feeder: device that supplies small components automatically)

(Air Chuck: pneumatic tool to grip/release objects)

(Single-Axis Robot: robot moving along one axis)

3. Stacking

This stage stacks the Mid-Planets with pins inserted.

A servo-type control system adjusts stacking positions according to thickness.

We applied a dual-set workflow, so while one set is being discharged, another can be processed simultaneously—eliminating any bottlenecks.

(Bottleneck: a production stage that slows down overall throughput)

4. Tray Placement

Finally, a Hyundai Robotics 6-axis industrial robot HH050 places the stacked parts onto a heat-treatment tray.

Each tray holds 9 sets × 2 layers. Once filled, a hoist removes the tray, completing one full cycle.

(Hoist: lifting device for heavy loads)

Q5. Why was Hyundai Robotics’ HH050 chosen over other robots?

Engineer Han:

There were several reasons. The HH050, being a 6-axis robot, is optimized for precise stacking and complex motions required in this project.

It ensures accurate tray placement and operates quickly and efficiently within limited space.

It also supports high payloads without compromising stability, making it ideal for handling heavy products.

Its durability and low maintenance needs provide the customer with long-term operational reliability, which was a decisive factor.

Q6. What benefits can the customer expect from this automation?

Engineer Han:

The greatest impact is workforce optimization.

Tasks that previously required 3–4 operators can now be handled by just one operator.

This dramatically improves ROI (Return on Investment).

Additionally, product quality consistency has improved significantly, reducing defect rates and greatly increasing productivity.

Q7. How is maintenance and system management handled?

Engineer Han:

We primarily manage the system through SoLlink, our integrated multi-robot monitoring platform.

If an issue cannot be resolved remotely, we quickly dispatch on-site service engineers.

We also provide one year of free A/S (after-service), ensuring stable system operation for the customer.

Example: SoLlink robot utilization data

Q8. How does Marosol build automation solutions across different manufacturing processes?

Engineer Han:

At Marosol, we don’t just deliver loading/unloading automation.

We design customized automation solutions across various manufacturing processes by first analyzing the customer’s production requirements and workflow.

We then select the optimal combination of robots, control systems, and sensors to meet technical needs.

In particular, loading/unloading automation is critical for maximizing accuracy and efficiency in repetitive tasks.

Our solutions enable precise, consistent operations using industrial robots and advanced automation equipment.

We also provide systems capable of automating pin insertion, stacking, and assembly, ensuring smooth integration between each stage.

Marosol Field Engineers – supporting customers even after deployment

Our strength is flexibility.

We don’t just automate a single process—we build modular, scalable systems that easily adapt to model changes or product variations.

This allows customers to maintain high productivity in a constantly evolving manufacturing environment.

We also prioritize after-service support, offering remote assistance and regular maintenance so customers can operate their automation systems with confidence.

Today, we spoke with Marosol’s Senior Engineer Jisub Han about a loading/unloading and heat-treatment automation project for an automotive parts manufacturer.

Marosol continues to gain recognition, successfully implementing automation solutions for major enterprises such as Samsung C&T and Incheon International Airport.

If you’re curious about finding an automation solution tailored to your processes, click the banner above or visit our website.

From free consulting and quotation, to deployment, design, and post-implementation service, Marosol is your trusted end-to-end partner.

Thank you! 🤗

👉 Visit our website here! 👇👇👇

Price Negotiation Available Now!

Additional discounts may be available depending on your needs.