Why Did Space Factory Choose Robotic Wood Assembly?

wood assembly automation / Space Factory / window frame assembly / KUKA industrial robot

Why Did the Carpenter Put Down the Nail Gun? 🪚

In 2025, a company named Space Factory introduced a new wave of innovation to the construction industry — they brought robots into the wood assembly process. 🤖

You might be thinking, “Wait, robots are driving nails into wood now?”

Well, this case will likely change your perspective.

Space Factory specializes in modular housing and implemented industrial robots to achieve consistent quality and build an efficient production system. As a result, they successfully automated the window assembly process — reducing work time by up to 40%.

But why bring in robots in the first place?

How did they manage to cut work time so drastically?

And what role did Marosol play in this transformation?

Let’s dive into the real story behind the automation. 🏃♂️

Window Frame Assembly — Now a Job for Robots, Not Carpenters? 🤔

Among all construction processes, window frame assembly is particularly labor-intensive. That’s because the frame varies in size and shape depending on the window type and requires precise joining.

In the past, skilled workers manually carried the wood, aligned it, and fastened it with nail guns or staplers. But that approach came with a few major issues:

✅ Limited production due to a shortage of skilled labor

✅ Larger workforce needed to handle custom orders

✅ Heavy lifting and repetitive tasks led to fatigue

✅ Complex environments made real-time monitoring difficult

To solve these issues, Space Factory turned to robotic automation.

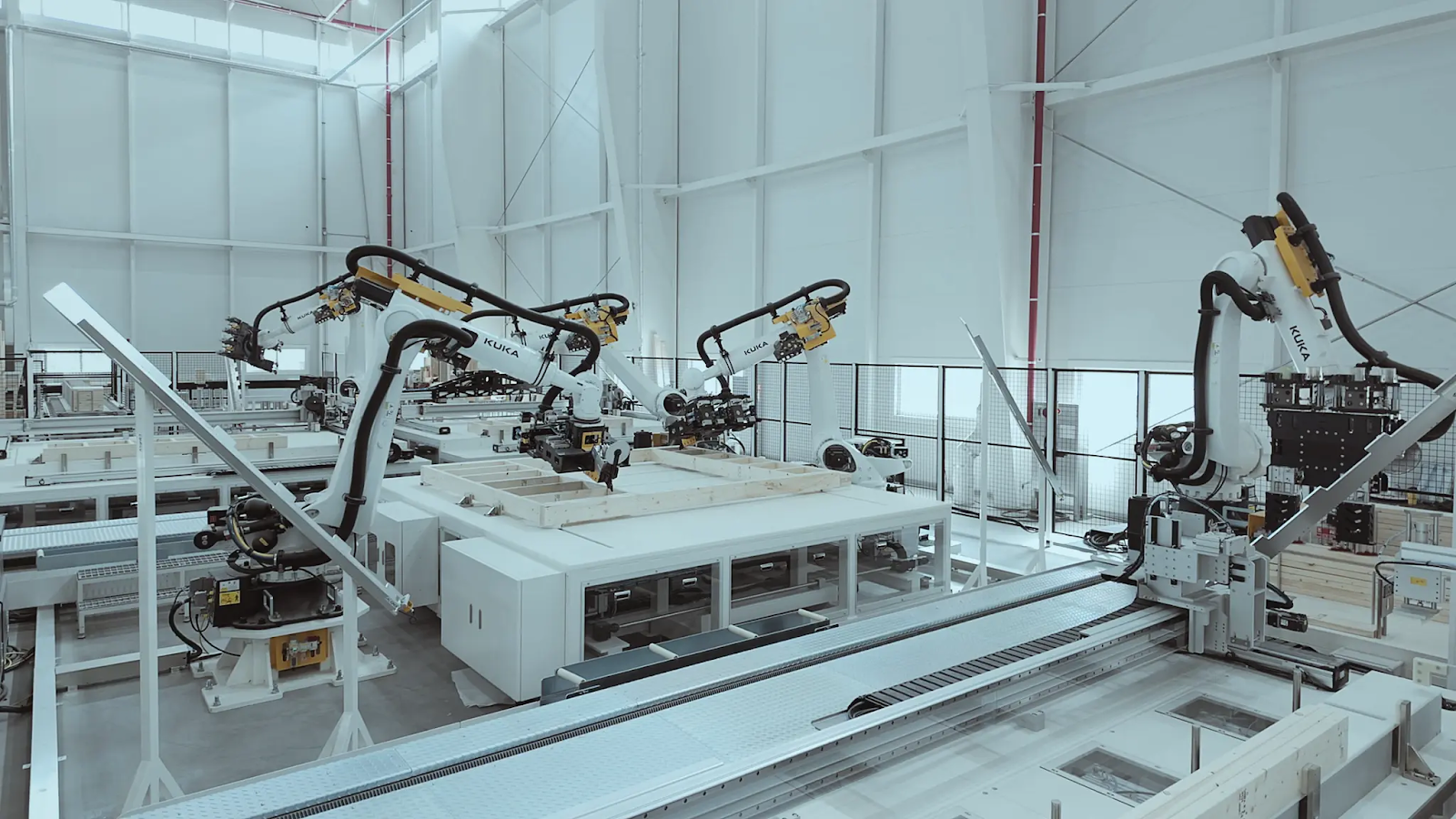

Marosol Solution #1: KUKA Robot + Custom Gripper + High Payload Track Motion

For this project, Marosol designed the optimal setup for automated window assembly.

🎯 Here’s what the system includes:

KUKA KR 210 R3100 Industrial Robot

Handles payloads up to 210 kg with a working radius over 3 meters — ideal for heavy, precise tasks.Custom-Designed Gripper

Detects and grasps wooden materials delicately and moves them into position.High Payload Track Motion

Extends the robot’s working area, allowing smooth transportation of heavy window frames across a wide space.

So, what happens when you combine these three?

The robot takes over the human roles of alignment → assembly → transfer, doing it faster and with greater accuracy.

Let’s take a closer look at how this automated line is structured.

At the Heart of the Line: KUKA’s Heavy-Duty Robot

The industrial robot from KUKA moves along a track motion system installed on the factory floor. Attached to the robot is a custom gripper designed specifically for wooden components.

This system integrates a 6-axis industrial robot with supporting devices for maximum efficiency. Space Factory chose the KUKA KR R3100 model, which handles loads up to 120 kg and has a 3-meter reach — perfect for large window frames and wooden panels.

Expanding the Robot’s Reach with Track Motion

The robot glides along the High Payload Track Motion, accessing multiple workstations along a long assembly table. This track acts like a linear rail, dramatically expanding the robot’s range.

It even enables transport of heavy wooden frames — sometimes weighing hundreds of kilograms — without the need for cranes or forklifts.

The Game-Changer: A Gripper That Does It All

Another essential element is the custom gripper. This tool picks up, aligns, and holds wooden parts securely — and even handles tasks like nailing or stapling, which used to be risky for human workers.

Equipped with pressure sensors and vision cameras, the gripper can detect the size and position of each component, ensuring precise placement every time.

Marosol Solution #2: Real-Time Monitoring with SOLlink INDUSTRIAL 🧠

Automation isn’t just about machinery — it’s also about control and oversight.

That’s why Marosol also deployed SOLlink INDUSTRIAL, a smart factory solution that monitors the production process in real time and instantly detects anomalies.

Developed by Bigwave Robotics, SOLlink is a cloud-based robot control platform that monitors and controls multiple robots and peripherals — all from a single interface.

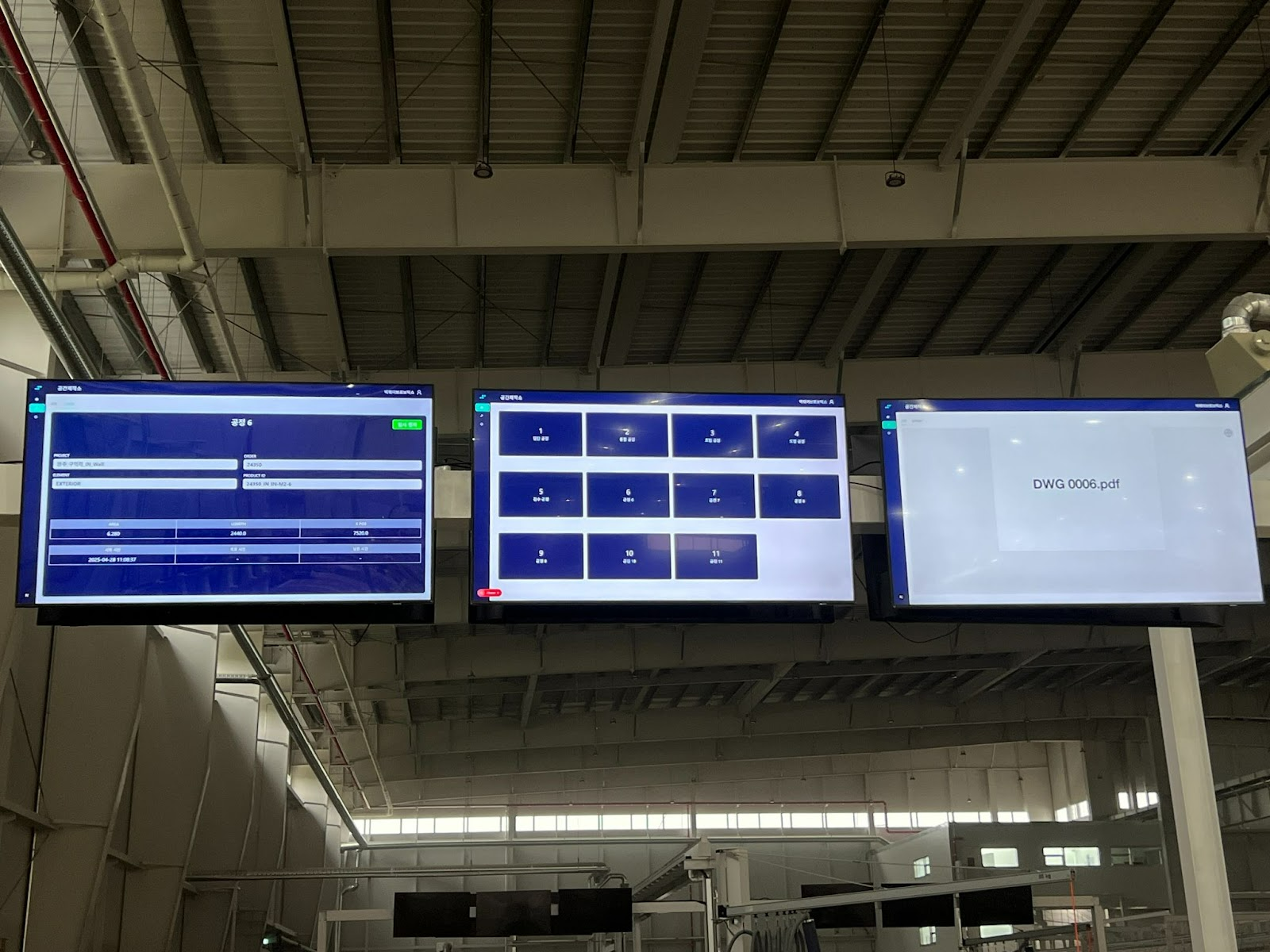

![Image: SOLlink INDUSTRIAL Installed at Space Factory]

Inside Space Factory’s plant, SOLlink tracks the robots' status and production progress in real time. Operators can send commands, collect and analyze data, and remotely control all systems. Even with future robot expansions, the unified platform ensures streamlined operations.

Thanks to SOLlink, unexpected issues are resolved instantly, and predictive maintenance is now possible through data-driven insights.

In the end, hardware like robots, grippers, and track systems seamlessly integrates with the software backbone provided by SOLlink — making Space Factory’s smart window assembly a reality. 🙌

See the Workflow at a Glance 👀

From Material Input → Window Assembly → Frame Transfer

Space Factory’s automation system focuses on assembling wooden window frames as part of modular panel production. The full process includes:

1️⃣ Material Input & Alignment

Pre-cut wooden components are loaded in.

Using BIM design data and SOLlink guidance, the robot aligns them to the exact position.

2️⃣ Window Frame Assembly

Once aligned, the robot drives nails or staples at precise locations.

It can flexibly handle 44 different window patterns, reducing manual intervention.

3️⃣ Frame Transfer to Next Station

Assembled panels are transferred to the next station by the robot via the track motion system.

Heavy frames are moved safely — no cranes or forklifts required.

In summary:

Material Placement → Frame Assembly → Panel Transfer — all handled by a single robotic cell.

Operators assist with material prep or final checks, while robots take care of the repetitive, dangerous work.

What Makes Space Factory’s Automation So Unique? 🔧

This isn't just mechanical automation — it’s a smart, flexible, and safe solution combining real-time management and precision.

✅ Supports 42+ Window Patterns

The system can assemble dozens of different designs and can be reprogrammed for new patterns. It’s ideal for modular housing where customization is key.

🎯 Consistent, Accurate Work

Robots perform repetitive precision tasks flawlessly.

Nail positions and spacing are always exact, resulting in higher insulation quality and smoother finishes — with fewer defects.

🦺 Safer Work Environment

Robots handle dangerous jobs like heavy lifting and nailing.

This reduces worker injury risks, lowers noise and dust, and improves workplace comfort.

Safety fences and sensors prevent collisions between humans and robots.

Marosol Is Here to Help 💪

Space Factory’s robotic wood assembly isn’t just a one-time innovation — it’s a blueprint for other industries.

This system can be adapted for light wood framing, furniture production, custom joinery, and any repetitive, semi-customized manufacturing sector.

Wondering if automation is possible in your industry?

Ask Marosol’s robot experts.

We partner with over 400 robot providers and maintain a database of 20,000+ automation cases, delivering custom-fit solutions across industries.

We can help you design the right automation for your factory floor.

A future where repetitive work is automated and humans focus on creativity —

It all starts with a consultation with Marosol. 👇

Price Negotiation Available Now!

Additional discounts may be available depending on your needs.