We automated 1-ton waste-material transport with autonomous mobile robots. (Deployed 2 units of KUKA AMR KMP 1500P)

Autonomous Mobile Robot That Hauls 1-Ton Waste Materials With Ease

SPACE FACTORY KUKA AMR KMP 1500P Deployment Success Story 🚚🤖

Heavy, repetitive handling. A tiring shop floor… Is there a better way?

In manufacturing, construction, furniture, and modular housing sites, moving heavy loads is unavoidable. In particular, when operators must manually move waste materials, metal rollers, or raw materials—multiple times per day, up to 1 ton per move—these challenges quickly add up.

Accumulated operator fatigue and musculoskeletal strain

Safety risks such as collision incidents and other on-site accidents

Operational instability driven by labor shortages

When these factors stack up, overall production efficiency naturally declines.

SPACE FACTORY, a specialized wooden modular-housing manufacturer, was no exception. While the site had made major investments in automation equipment, waste-material transport across the plant still relied heavily on manual handling. Operators had to travel a long-distance route of approximately 1.2 km—back and forth multiple times a day—and the constant concern of “What if an accident happens?” followed them like a shadow. 😨

“Unlike the automated processes, waste transport was entirely dependent on people. Fatigue kept building up, and the safety burden grew as well.”

— SPACE FACTORY Site Manager

The logistics challenges SPACE FACTORY faced as a wooden modular-housing manufacturer

Does this sound similar to your facility as well? 👇

✅ Heavy loads in the 500–1,500 kg range must be moved repeatedly.

✅ Operators repeatedly travel a long route of up to 1.2 km, increasing fatigue and on-site safety risk.

✅ Even if you want to add headcount, staffing is limited—naturally leading to lower productivity.

✅ Core production processes are already automated, but internal transport still depends on people—creating a disconnect between production and logistics.

This is where Marosol identified the answer: “Let’s redesign the material flow through AMR-based transport automation.”

Marosol’s Solution: AI-Based Autonomous Intralogistics Automation System

KUKA AMR KMP 1500P × SOLlink for end-to-end transport-route automation

Selected Solution

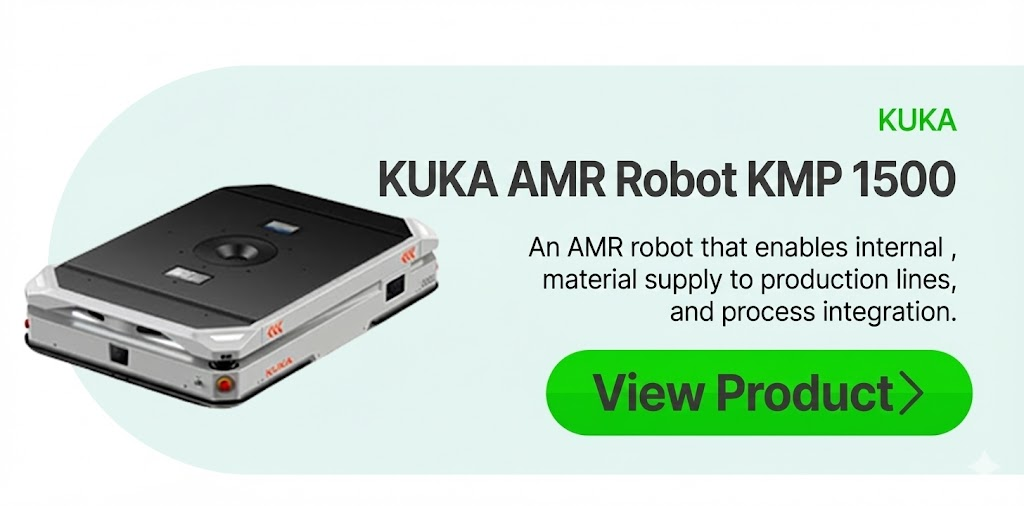

Deployed Solution: Two (2) KUKA AMR KMP 1500P Units

Payload: Up to 1.5 tons (sufficient for waste materials and raw-material transport)

Autonomous navigation (SLAM)-based dynamic route planning and response

3D LiDAR: Safety bumper, speed reduction, obstacle avoidance, and safe operation even in mixed-traffic environments

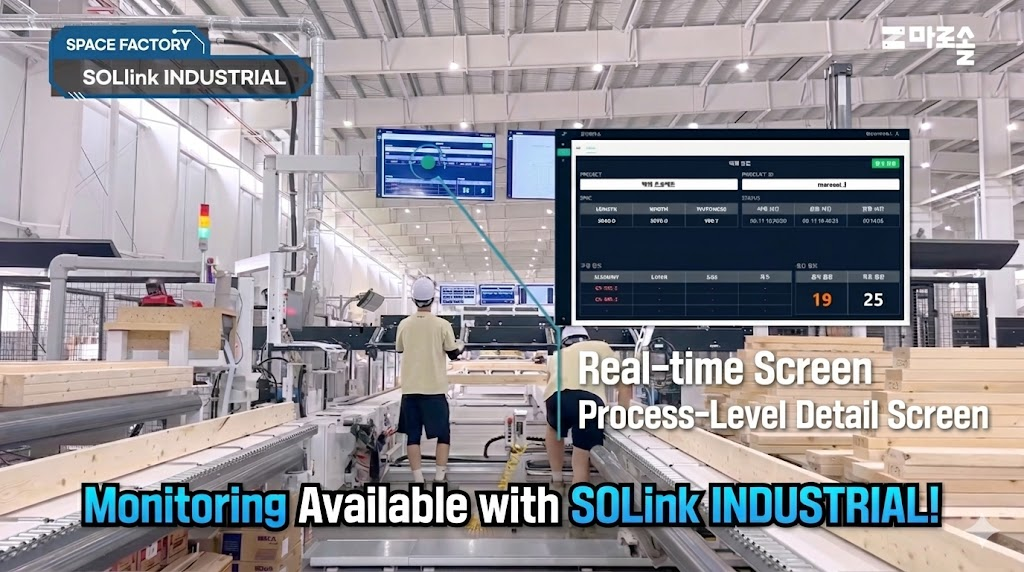

SOLlink INDUSTRIAL

Integrated monitoring and operations automation for factory robots and equipment

Real-time monitoring of production equipment and robot sensor status

AI-based automatic detection and alerting for anomalies and errors

Automated analysis dashboards for production volume, defect rate, and operating KPIs

Integration with existing systems such as MES and ERP, and linkage with autonomous robots

Easy scalability by adding new robots/equipment with minimal effort

Real-time control and report visibility anytime via PC or mobile

Why KUKA AMR KMP 1500P?

Because SPACE FACTORY had already invested heavily in process automation, they wanted a logistics robot solution that was both “simple to deploy” and “highly reliable.” From that perspective, the KUKA AMR KMP 1500P was an ideal fit.

With a 1.5-ton payload, it can comfortably cover up to 1-ton waste transport needs

Enables fully unmanned transport by automating pickup and drop-off with an electric cart

SLAM + 3D LiDAR provides strong navigation stability even in dynamic shop-floor environments

When integrated with SOLlink, it supports multi-unit fleet operation, prioritized routing, and remote monitoring in a stable, production-ready manner

In the future, the scenario can be expanded further—for example, pallet loading, integration with process-based call/dispatch triggers, and long-distance unmanned night operations. This made it a particularly strong fit for large-scale manufacturing environments like SPACE FACTORY.

Why SOLlink INDUSTRIAL?

For the KUKA AMR KMP 1500P to operate reliably on the factory floor, it’s not enough to manage only the robot itself. What’s needed is an integrated operations environment where the robot is connected seamlessly with the entire process and equipment.

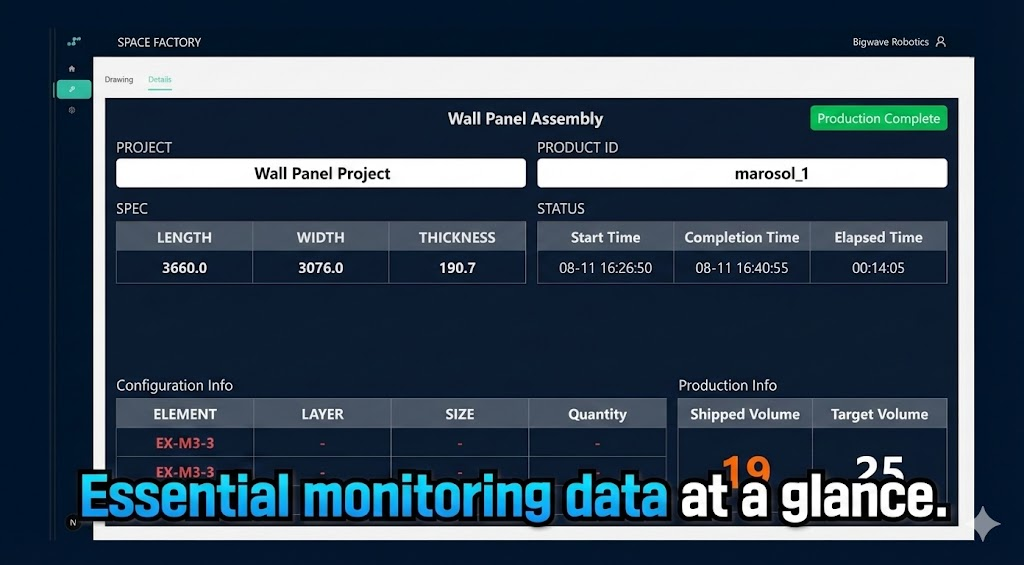

That’s why Marosol proposed SOLlink INDUSTRIAL together with the robot. SOLlink INDUSTRIAL makes it possible to manage the entire plant in real time from one place—like a “smart factory control tower.” Unlike traditional systems such as MES or SCADA, it is designed around robot-centric workflows, making on-site execution more intuitive and operationally aligned.

The core value of SOLlink INDUSTRIAL is that “everything can be managed from a single screen.” Instead of walking across a large facility, you can simply open a PC or smartphone and check everything in real time, including:

Robot location, battery level, and job status

Equipment operating status

Production flow and bottlenecks

When needed, you can also remotely start or stop tasks.

Automatically analyzing operational data is another major advantage.

SOLlink organizes and visualizes key metrics—such as robot travel distance, transport counts, avoidance events, production volume, and defect rate—automatically. This helps managers quickly identify bottlenecks and operate work schedules and staffing more strategically.

And it’s highly scalable, too.

Even if you add new robots or expand the line, you can scale simply by adding “lego blocks,” and integration with existing systems like MES and ERP is straightforward. That’s why management complexity doesn’t increase dramatically even as the plant grows or the robot fleet expands.

In summary, SOLlink INDUSTRIAL is a digital control tower for plant operations—bringing together robot operations, equipment monitoring, AI-based anomaly detection, operational data analytics, and scalability in one platform.

That’s why, in the SPACE FACTORY case, the goal wasn’t simply to deploy KUKA AMRs as autonomous transport robots. It was to build an integrated operating environment where the entire factory runs as one connected system—by introducing SOLlink INDUSTRIAL.

“We deployed two KUKA AMRs into the plant with SOLlink, optimized routes and scheduling, and enabled intersection-priority control to reduce stops and collisions—achieving fully autonomous transport.”

— Marosol Robotics Specialist

SPACE FACTORY Intralogistics Automation

Here’s how the operation runs (real on-site scenario)

Daily intralogistics work begins by reserving the number of transport missions and the operating time window in the SOLlink interface. After that, the robot automatically moves to the standby point and prepares for the day’s operation.

When needed, it picks up waste materials automatically under the electric cart. If it encounters complex intersections or high-traffic areas, it independently determines whether to stop, yield, or proceed, ensuring safe navigation.

At the destination, it automatically lowers the load, then immediately prepares for the next mission. When the battery level drops, it autonomously returns to the charging dock.

All of these steps can be summarized and reviewed through SOLlink’s reporting features—including mission count, travel distance, task duration, and avoidance events—so managers can quickly monitor performance and operations.

Results After Deployment:

80 Automated Transports per Day — People Focus on Higher-Value Work! 🎯

Once two KMP 1500P autonomous transport robots started operating, the site began to change noticeably.

Quantified Improvements (Case Reference)

✓ 80+ automated transports per day achieved (waste transport: loading area ↔ disposal area)

✓ With the same headcount, material-handling throughput improved by ~2×

✓ Reduced musculoskeletal strain and injury risk for operators

✓ Lowered collision risk from electric-cart traffic

✓ Less time spent walking between work areas, enabling operators to stay focused on production tasks

✓ Established a 24/7 response foundation through night-time charging → automated transport cycles

As two KUKA AMR KMP 1500P units ramped up full operation, SPACE FACTORY’s shop floor quickly transformed. Previously, staff had to manually push or move waste materials multiple times a day—yet now, the robots travel across the facility and automatically transport waste from the loading area to the disposal yard.

Most notably, the overall flow of transport operations improved. The two KMP 1500P units completed 80+ missions per day, replacing much of the heavy transport work that previously required direct manual handling. As a result, staff fatigue and physical burden were significantly reduced—and this wasn’t just a convenience upgrade. It delivered a step-change improvement, with internal logistics efficiency increasing to nearly double.

Above all, on-site satisfaction showed up more strongly in safety than in “productivity.” In the past, moving nearly 1-ton waste loads with an electric cart could cause shaking or slipping on ramps, and incidents such as tripping or impact injuries to the hands, neck, or lower back were not uncommon. However, the KMP 1500P continuously assesses its surroundings using 3D LiDAR, a safety bumper, and speed-reduction/stop algorithms, significantly lowering the risk of people getting hurt. In fact, the site also shared feedback that, not long after deployment, the number of operators complaining of hip and shoulder pain dropped sharply.

Voices from the Floor

Employee responses after directly experiencing the robot deployment have been highly positive.

A production management lead said,

“Back then, two to three people had to handle this all day. Now, two robots are processing it reliably,”

adding that both logistics responsiveness and operational stability improved significantly.

A shop-floor operator shared,

“My hip and shoulder fatigue has noticeably decreased. I don’t have to worry about the cart tipping over like before,”

highlighting the safety improvements.

Management also noted,

“We can assign dangerous and physically demanding work to robots, and our employees can focus on more important tasks,”

saying that both job focus and overall team morale improved.

Mini FAQ (Top Questions from On-Site Operations Teams)

Q1. The aisles are narrow and there are many people—Is it safe?

A. Yes. With 3D LiDAR, safety bumpers, and speed reduction/stop logic, the AMR can operate safely in mixed-traffic environments. You can also set safe speed profiles by zone for site-specific operation.

Q2. Can we keep using our existing carts?

A. Yes—if the undercarriage structure is compatible, pickup via lifter mechanism is supported. If needed, we can also provide a dedicated cart.

Q3. What if we don’t have enough power / charging infrastructure?

A. We place autonomous docking stations in optimal locations to minimize charging bottlenecks. SOLlink also manages the charging schedule.

Q4. Can we check robot status or control it remotely?

A. Yes. With SOLlink INDUSTRIAL, you can connect from anywhere via PC or mobile to monitor robot location, battery, and job status in real time—and send commands such as dispatch, stop, or job changes. This also supports unmanned operation at night or on weekends.

Q5. If we add more robots later, do we need to rebuild the system?

A. No. SOLlink INDUSTRIAL scales like adding “lego blocks”—even if you add more robots, it expands within the same monitoring environment.

SPACE FACTORY’s Achievements 📈

Thanks to the autonomous intralogistics automation system built with Marosol, SPACE FACTORY improved not only “making transport easier,” but the overall operational structure on the shop floor.

Improved Safety

Risks of cart tipping and operator injury dropped significantly, and the likelihood of safety incidents was visibly reduced.

Better Quality

With less time spent away from the production line, operators can stay focused on their core tasks, and overall production flow became smoother.

Lower Operating Costs

As labor required for repetitive transport decreased, TCO dropped—and the same workforce can now handle higher throughput.

Scalability Secured

The operation is now structured to expand capacity further, including support for unmanned night and weekend operation.

Wrap-up: “People focus on core work — heavy transport goes to robots.”

SPACE FACTORY’s deployment of the KMP 1500P is a representative example of how autonomous intralogistics automation can improve both safety and productivity on the shop floor.

By shifting repetitive “transport” tasks to an AI-enabled intralogistics automation system, you can address labor constraints, safety risks, and operational inefficiencies in one move.

Could this work at your site?

Marosol is a total robotics solution platform that provides:

100+ proven, on-site consulting engagements

A broad partner network, including KUKA AMRs

End-to-end support from “design → demo → deployment → monitoring/control (SOLlink) → operational optimization,” all in one place

Now is the time to reset the standard for factory intralogistics with autonomous transport robots.

With the KUKA AMR KMP 1500P and SOLlink INDUSTRIAL monitoring/control, a safer and more efficient operation is achievable—starting today.

Leave your contact details and inquiry via the “Contact Us” banner below, or call our main line for a quick consultation.

☎ Main phone: 080-858-5050

✉ Main email: hello@bigwaverobotics.com

👇 Apply now for a free logistics robot consultation! 👇

Get AI-based Logistics automation consulting tailored to your factory

Price Negotiation Available Now!

Additional discounts may be available depending on your needs.