Boosting Productivity by 370% with Assembly Automation Success with EPSON SCARA Robots!

Boosting Productivity by 370% with Assembly Automation 📈 Success with EPSON SCARA Robots!

💡 In just 5 minutes, you’ll learn :

What is a SCARA robot?

A real-world case of assembly automation using EPSON SCARA robots

How EV console assembly automation works

What makes this project unique

How to ensure 100% success with SCARA-based automation

Assembly Automation with SCARA Robots

What happens if we let robots take care of product assembly? 🤔

Imagine picking up a tiny screw that’s barely visible to the naked eye and fastening it precisely into a hole as small as a pinhead. Can a robot do that? The answer is YES—and with even higher quality. In fact, robots can perform screw-fastening more delicately and with consistent torque compared to humans.

Assembly automation with robots is widely used across industries, especially in repetitive and precision-driven screw-fastening tasks. By implementing assembly automation, manufacturers can achieve consistent quality, reduced cycle times, and lower labor costs.

For delicate and repetitive processes like screw fastening or pick-and-place operations (picking up parts and placing them in exact positions), one type of industrial robot stands out: the SCARA robot.

What is a SCARA Robot?

A SCARA (Selective Compliance Assembly Robot Arm) robot is a four-axis industrial robot designed for high-speed, high-precision assembly tasks. It is particularly specialized in horizontal movements and offers flexible motion along specific axes, enabling fast and accurate operations.

Leading SCARA robot manufacturers include EPSON, FANUC, and YAMAHA—all known for their advanced precision control technology.

Today, we’ll take a closer look at a real-world case: how an EV console manufacturer successfully automated assembly processes using EPSON SCARA robots, with insights from Marosol robotics expert, Jiseop Han.

Q1. What kind of company introduced assembly automation this time?

The company manufactures center consoles for electric vehicles (EVs). These consoles, located between the driver’s and passenger’s seats, house key components such as cup holders, storage compartments, and gear shift levers.

The goal of this automation project was to establish a fully automated line for assembling console parts.

Q2. Why did the company decide to implement automation?

Previously, the EV console assembly line required 40–60 workers on average. Securing enough space and recruiting sufficient staff posed major challenges.

Moreover, because the entire process was manual, the workload was physically demanding. As a result, high turnover and frequent workforce changes disrupted production. To address these issues, the company decided to adopt screw-fastening automation.

Q3. Which robots were used in this project?

The project deployed two types of EPSON SCARA robots: the LS-b Series and the C Series.

The LS-b Series handles vertical screw fastening.

The C Series, equipped with 6 axes, is used for side fastening, particularly for screws located in hard-to-reach console areas.

Q4. Why choose EPSON SCARA robots?

Seiko EPSON is a global leader in robotics and precision engineering. Their SCARA robots are proven in the market, with the LS-b Series ranking #1 in global SCARA market share for 12 consecutive years.

1. High Precision & Reliability

The LS-b and C Series are optimized for precision tasks, delivering consistent performance even in repetitive assembly.

The LS-b Series offers ±0.02mm repeatability, ensuring flawless accuracy for processes where even tiny errors are unacceptable.

The C Series excels in side fastening within tight spaces, boosting efficiency in complex assembly lines.

2. Space & Cost Efficiency

The LS-b Series provides compact design with powerful performance, making it ideal for maximizing productivity in limited spaces. The C Series, designed for easy integration, also reduces installation and maintenance costs.

3. Flexible Application

The customer needed a solution capable of adapting to diverse assembly processes. The LS-b and C Series met these requirements perfectly, allowing smooth adjustments for different product sizes and process variations without major reconfiguration.

Q5. Can you walk us through the assembly automation process?

Here’s how the entire EV console assembly line works:

Step 1. Assigning IDs via LOT System

Each console part type is registered in the LOT production system, where product numbers and production data are managed.

Step 2. Preparing Parts

Operators set screws and bolts, which are scanned via barcodes to detect errors or missing parts before robots begin assembly.

Step 3. Conveyor-Based Line

For large console parts like wireless chargers and cup holders, a conveyor flow line was implemented due to their size and fastening positions.

Step 4. Standalone Module Line

For the main body, where assembly spaces are tight, a small standalone robot line was deployed.

Step 5. Multi-Part Assembly Line

For the structural “pillar” part of the console, three parts must be assembled into one. This line required the most robots, using both LS-b and C Series to handle vertical and side fastening.

Q6. What makes this project different from similar ones?

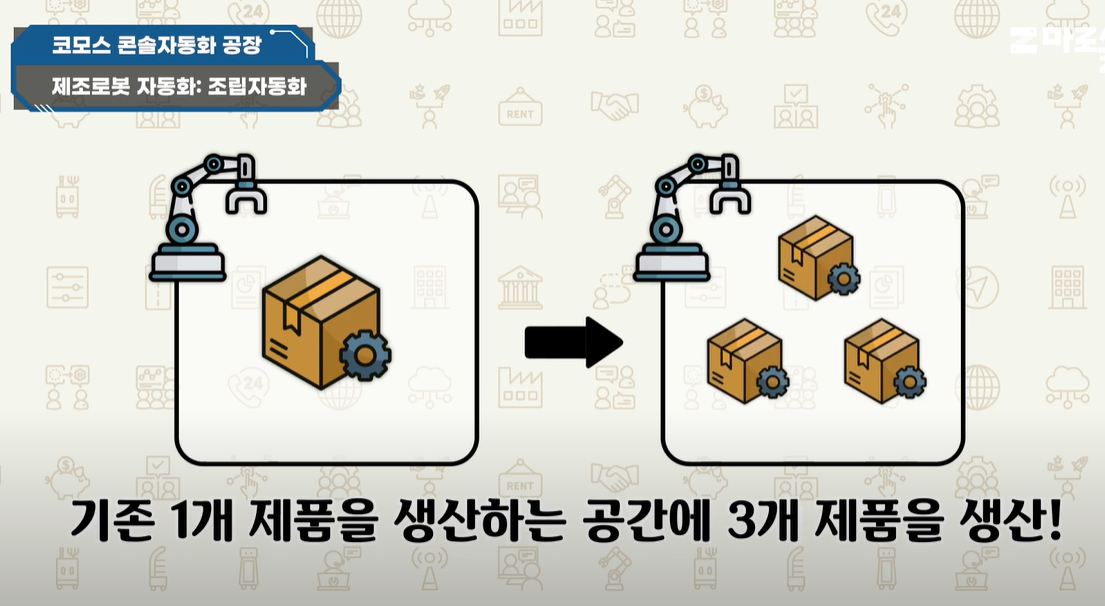

1. Maximized Efficiency

By designing compact robots and modular layouts, the team enabled three different product lines in the space where competitors could only manage one. Workforce needs were reduced from 40–60 people to fewer than 30.

2. Maximized Flexibility

Unlike typical conveyor-based automation, this project used modular automation to quickly adapt to variations in product size, sequence, and vehicle options.

Q7. How is system maintenance and management handled?

Step 1. SOLlink Integrated Control System

If issues occur, Marosol’s in-house system, SOLlink, monitors robots from multiple manufacturers in one interface, enabling quick diagnostics and troubleshooting.

Step 2. Nationwide On-Site Service

If remote solutions are insufficient, Marosol experts or certified SI partners provide on-site maintenance services across the country.

Q8. How can companies adopt assembly automation through Marosol?

Simply click the banner below for a free consultation and quotation. Marosol’s automation experts are available 24/7 to guide you through consulting, cost estimates, implementation, and after-sales service.

Final Thoughts

Today, we explored how an EV console manufacturer successfully boosted productivity by 370% through assembly automation with EPSON SCARA robots, guided by Marosol’s robotics expertise.

Marosol has also delivered automation solutions for Samsung C&T, Incheon International Airport, and other major clients.

If you’re curious about automation tailored to your production line, visit the Marosol website or click the banner above. From free consulting to full implementation and maintenance, we’ll take care of everything for you. 🤗

Price Negotiation Available Now!

Additional discounts may be available depending on your needs.